The University of Mostar has already used the provided resources by the Erasmus+ project KnowHub to begin the process of building lasting relationships with enterprises in Bosnia and Herzegovina. Let’s hear from the University of Mostar on the ongoing process.

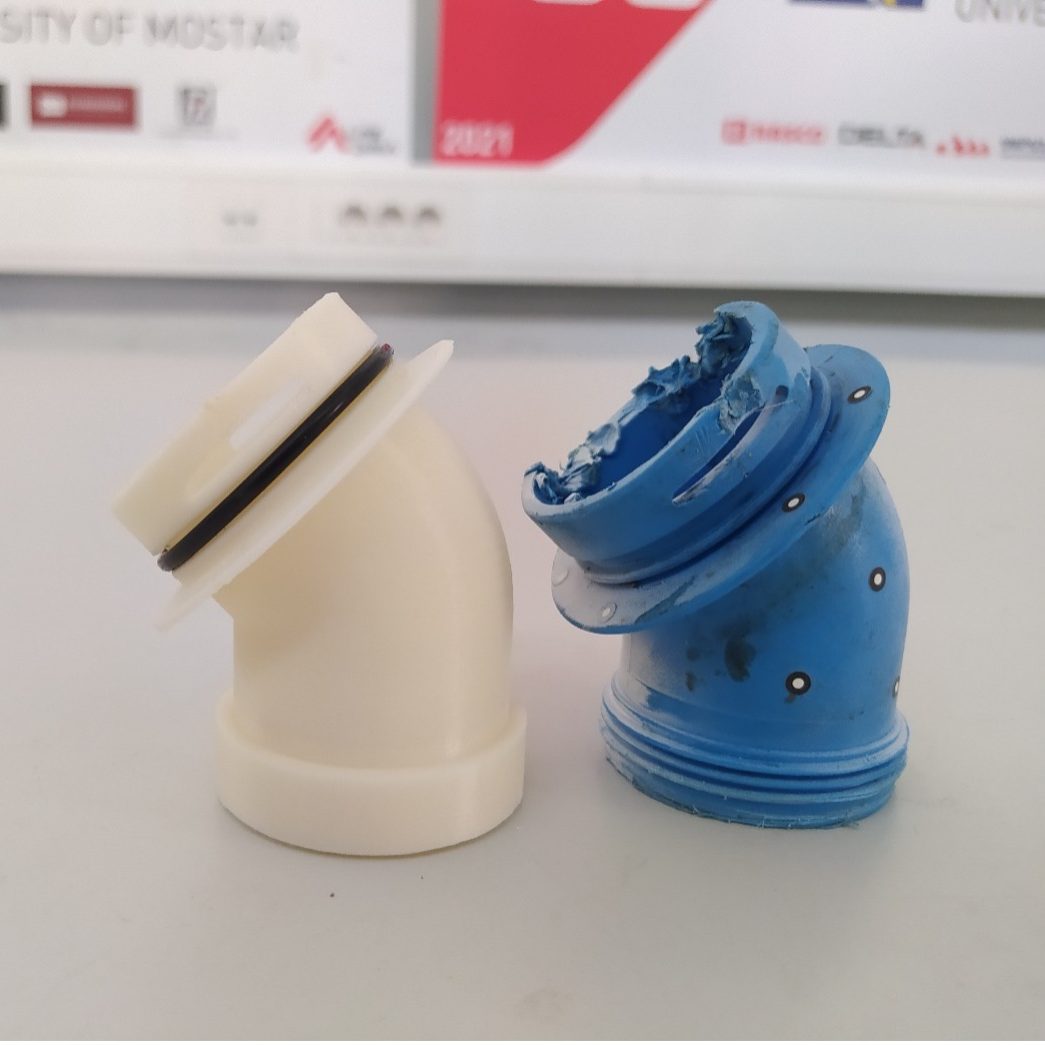

Half a year ago, the University of Mostar acquired six high-quality 3D printers through the Know Hub project, including an industrial 3D printer (Stratasys F270). So far, they have had a sustainable number of projects with local companies and institutions where the University used equipment for rapid prototyping using optical scanning technologies, digitized model processing software, and 3D printing. In one of their most recent projects, UOM cooperated with a pool maintenance company to help them develop a 3D model of a used elbow pipe, which is very difficult to procure.

“The first step was to digitize the damaged piece using an optical scanner, and then we created the 3D model. In the next step, we printed the 3D model using the 3D printers. We used quality ASA material to ensure that we met all requirements, such as resistance to higher temperatures, resistance to UV radiation, and better mechanical properties. Thus, we developed and produced a replacement part for a broken elbow pipe, utilizing rapid prototyping technologies.”